Production capabilities

The machinery in Piotrków Trybunalski is over 34,500 sq m of production area. Our machines include numerically controlled horizontal drilling and milling machines: Juaristi, Union PR150 and Union PCR 150, turning and boring lathes, draft and screw-cutting and facing lathes.

Download our service catalog

Metal cutting

We offer metal cutting services with gas and oxygen burners, plasma cutting with a 3D head and water cutting PTV CM / CAD.

Automated profile cutting line – Multiprofiler 3D by Stigal

The device enables plasma cutting of steel profiles up to 12 meters in length and with a cross-section of up to 300 x 600 mm. The device is capable of cutting various types of profiles, including: I-beams, T-beams, channels, angles, H-beams, flat bars, as well as closed profiles – rectangular and square.

Plasma cutter Onyx Vortex 3D FL ECKERT

Possibility of cutting sheets measuring 3000 × 12000 mm with the use of the Kiellberg HiFocus 360i neo plasma unit and a cutting thickness range of 0,5-80 mm depending on the material.

Machining

In our offer we also have a large CNC machining.

Our main equipment:

Juaristi TS5 MG30 CNC Machining Center SIN840D

[X] 6000 mm – horizontal level ride

[Y] 3500 mm – vertical level ride

[Z] 2500 mm – spindle extension

[W] 1000 mm – linear spindle alignment

2500×4000 mm – rotary table up to 22 tons

Union PRC150 CNC + Utronic Center

[X] 11000 mm – horizontal level ride

[Y] 3000 mm – vertical level ride

[Z] 1000 mm – spindle extension

[W] 700 mm – linear spindle alignment

150 mm – spindle diameter

2500×4000 mm – rotary table up to 22 tons

Union PR150 CNC SIN840D Machining Center

[X] 14000 mm – horizontal level ride

[Y] 3500 mm – vertical level ride

[Z] 1000 mm – spindle extension

[W] 700 mm – linear spindle alignment

150 mm – spindle diameter

2500×2500 mm – rotary table up to 20 tons

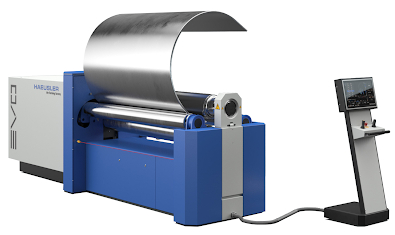

Other heavy machines include lathes, milling machines, drills, plate and gate drills, rotors, surface and shaft grinders, hydraulic and edge presses, rollers, etc. The weight of large-size elements can reach up to 150 tons and the turning diameter can reach from 0,03 m to 3,2 m

Welding

Welding at Zamet Industry is based on Workshop Welding Procedure Specifications (WPS), developed according to implemented welding technologies in accordance with EN ISO 15614-1, NORSOK M-101, DNVGL rules, LR, and other customer requirements.

The column and boom welder CBA 460M

The column and boom welder allows for welding of plates within a working range of 5000 mm x 4000 mm, enabling the welding of components up to 12 meters in length and weighing up to 40 tons. The welding technologies utilized by this device meet the highest standards, including ISO 15614-1, DNV Rules, and Norsok M101.

Cranes lifting capacity

We have overhead cranes with a lifting capacity of 40 + 10 tons, 20 + 20 tons, 16 + 16 tons, 15 tons, 12.5 + 12.5 tons, 10 + 10 tons, 10 tons, 8 tons, 5 + 5 tons , 5 tons, 4.5 tons, 3 + 3 tons and 3 tons, which allow to lift elements weighing up to 55 tons (tandem) up to a height of 14.2 m.

We are also able to lift items weighing 80 tons (and more) using self-propelled cranes, thanks to cooperation with a company offering such services.

Anticorrosion

We offer:

2 Shot blasting chambers :

- blasting chamber no. 1 – 5m wide × 4 m high ×15 m long

- blasting chamber no. 2 – 44.5 m wide × 4.5 m high × 25 m long

- painting chamber no. 1 – 5.9 m wide × 5.8 m high × 45 m long – including sectional doors, the possibility of dividing the cabin into 4 sections

- paint chamber no. 2 – 5.8 m wide × 5.8 m high × 50 m long – including sectional doors, the possibility of dividing the cabin into 3 sections thanks to that we can offer complex anticorrosion services under Frosio inspection.

Tests

We have qualified personnel to carry out NDT tests (non-destructive testing):

- VT – visual tests;

- PT – penetration tests;

- MT – magneto-powder tests;

- UT – ultrasonic examination.

We also carry out RT (radiography) tests at the plant. The tests are performed as part of our service by an external company.

3D MEASUREMENT

For 3D measurements we use the following devices in Zamet Industry:

- Laser-Tracker – AT-403 Leica (working temperature from -15 to 45 degrees / measuring range with a diameter of 160 meters);

- Measuring arm – Romer 75-30 (measuring range with a diameter of 3 meters / measuring accuracy 0.02 mm);

- Industrial total station – Leica TDA 5005 (measuring range with a diameter of 120 meters / measuring accuracy 0.2 mm).

3D measurement

For 3D measurements we use the following devices in Zamet Industry:

- Laser-Tracker – AT-403 Leica (working temperature from -15 to 45 degrees / measuring range with a diameter of 160 meters);

- Measuring arm – Romer 75-30 (measuring range with a diameter of 3 meters / measuring accuracy 0.02 mm);

- Industrial total station – Leica TDA 5005 (measuring range with a diameter of 120 meters / measuring accuracy 0.2 mm).

Assembly – testing site

On the Zamet Industry site we have assembly and testing site for large-size steel structures. The site The is equipped with a tower construction as a technological aid and allows testing outside the production hall.

Dimensions of the testing site – 25 × 35 m

Load capacity – 11 t / m²

Clean assembly hall

Our facility also has a modern clean assembly hall of 1,400 m², which provides the possibility of installing specialized hydraulic and electrical systems and other mechanisms in non-standard and large-size structures and machines.

© Copyright 2025 ZAMET

Realizacja: YC